About Our client

In the summer of 1996, Hyundai Corporation and Kinemetrics collaborated to develop a real-time monitoring system for the Namhae Bridge in South Korea. The bridge is owned by the Ministry of Land, Infrastructure and Transport (MOLIT).

Project Objective

The objective of this project was to enhance public safety by leveraging a state-of-the-art monitoring system to support more informed management decisions. This was achieved by:

- Calibrating Finite Element Models: Collecting ambient vibration data to accurately calibrate finite element models of the bridge.

- Conducting Fatigue Analysis: Capturing strain data to perform thorough fatigue analysis.

- Extreme Event Monitoring: Providing real-time monitoring during extreme events to assist bridge operators.

- Long-Term Health Monitoring: Continuously gathering ambient vibration data to ensure ongoing structural health monitoring.

Project Achievement

Kinemetrics, in collaboration with Agbabian Associates of Pasadena, California, and Batu Engineering of Seoul, South Korea, successfully installed the monitoring system in the fall of 1996.

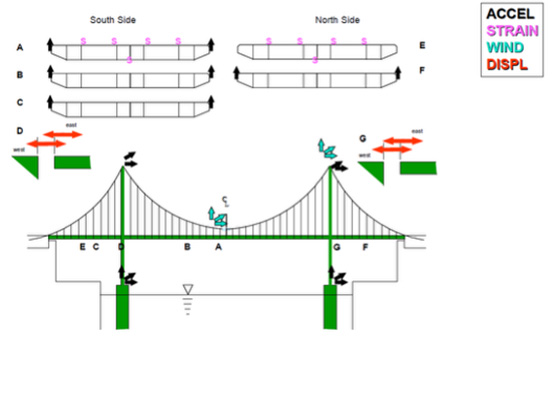

The system monitored the bridge using 16 channels of acceleration data, 6 channels of wind data, 10 channels of strain data and 4 channels of displacement data. These data streams were captured using two Kinemetrics Altus data loggers, with event data recorded via a PCMCIA recording module. Real-time data was transmitted via fiber-optic cable to the operations center, where an integrated Analysis/Display subsystem, a computer equipped with a large color monitor running OASIS software, processed and displayed the data on a single screen.

The primary advantages of this system include remote real-time display, proactive alerting, and event-triggered recording. In early 1997, Hyundai Corporation employed the system for ambient vibration monitoring and load testing. The strain data collected was also used for fatigue studies to estimate the remaining life of critical components.